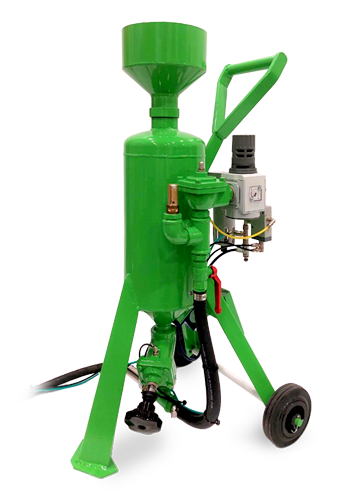

The Pressure BASE recovery sandblaster is an innovative solution to fully address and resolve issues related to environmental impact and safety. Thanks to its advanced technology, this machine significantly reduces the preparation time for shielding the surface to be treated and eliminates issues related to the recovery of abrasive materials.

The sandblasting unit is equipped with a single-phase motor characterised by a cartridge filter with a conical base. Thanks to an innovative cartridge shaking system, a vibration action is performed, thanks to which the dust accumulated on the filter surf

Applications of the Pressure BASE Recovery Sandblaster

The Pressure BASE recovery sandblaster is an innovative solution to fully address and resolve issues related to environmental impact and safety. Thanks to its advanced technology, this machine significantly reduces the preparation time for shielding the surface to be treated and eliminates issues related to the recovery of abrasive materials. Some of the most interesting applications of this technology are as follows:

-

Cleaning and Polishing Welds on Stainless Steel Products

Used as an ecological alternative to the use of chemicals, the Pressure BASE recovery sandblaster is ideal for cleaning and polishing welds, ensuring perfectly clean and contaminant-free surfaces.

-

Cleaning and Executing Writings and Decorations

Effective for work on marble, glass, crystal, wood, steel, and ABS, this recovery sandblaster allows precise writing and decoration without damaging the surrounding materials.

-

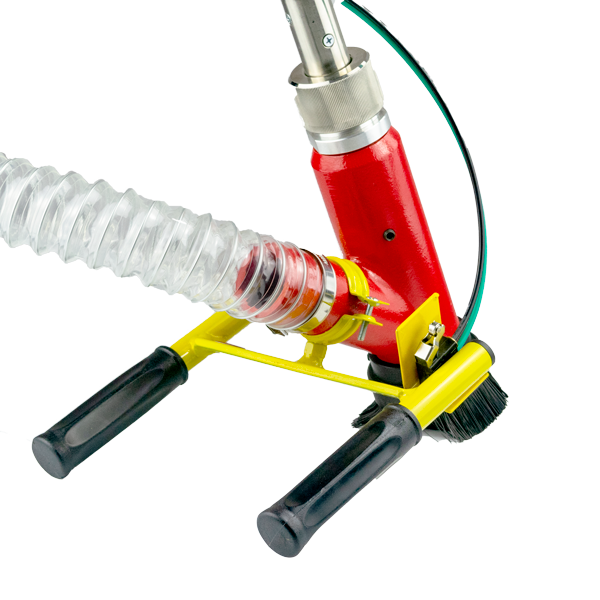

Sandblasting of Cylinders After Mechanical Processing

After lathe operations, the recovery sandblaster can be used to clean the cylinders. It is possible to automate the sandblasting cycle by locking the brush head with a tool holder clamp.

-

Localized Interventions on Metal Artifacts

Perfect for targeted sandblasting on metal artifacts or weld seams, this machine avoids damaging or affecting adjacent parts, preserving the integrity of the artifact.

-

Cleaning of Architectural Details

Ideal for interventions on stairs, stone, marble, or granite balconies. The Pressure BASE recovery sandblaster allows cleaning without interrupting the passage of people, without the need to empty premises or protect furniture and machinery.

-

Stripping of Metal Surfaces

In industrial, nautical, and steel sectors, this sandblaster is perfect for stripping metal surfaces. It is particularly useful in situations where open-air sandblasting cannot be used or where it is necessary to work in closed environments, offering an efficient and safe solution for paint removal.

Thanks to these applications, the Pressure BASE recovery sandblaster stands out as an excellent choice for those seeking efficiency, safety, and environmental respect.

The innovative cartridge shaking system performs effective cleaning by discharging the dust accumulated in the appropriate container

Want to know more about Pressure Base recovery sandblaster? Fill out the form below and we’ll get back to you soon