Sandblasting is a crucial process in surface treatment, especially in industrial and construction sectors. The continuous bag recovery sandblaster is one of the most significant innovations in this field, offering numerous advantages in terms of efficiency, safety, and sustainability.

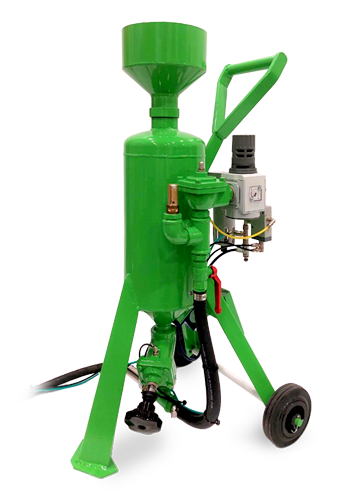

The FEVI Pressure Bag model represents one of the most advanced solutions available on the market. This continuous bag recovery sandblaster is designed to ensure maximum efficiency and operator safety. Thanks to its continuous bag collection system, the operator never comes into direct contact with the dust, thus reducing the risk of exposure to hazardous substances.

What is a Continuous Bag Recovery Sandblaster?

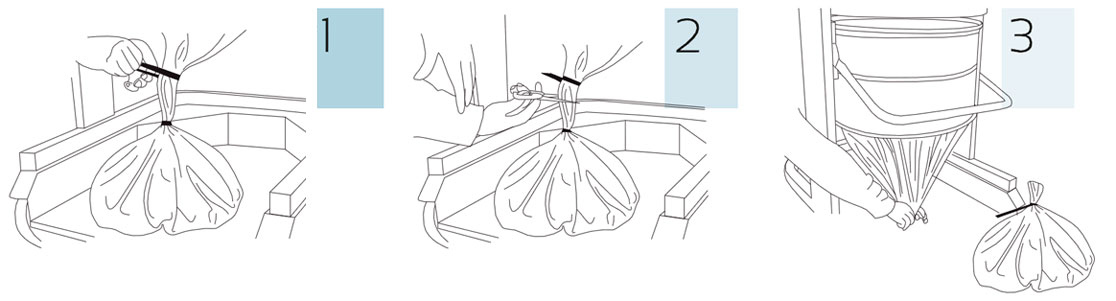

A continuous bag recovery sandblaster is a machine that uses a recovery system to collect and recycle the abrasive used during sandblasting. This system ensures that dust and residues are collected in a continuous bag, eliminating the need for the operator to come into direct contact with hazardous dust.

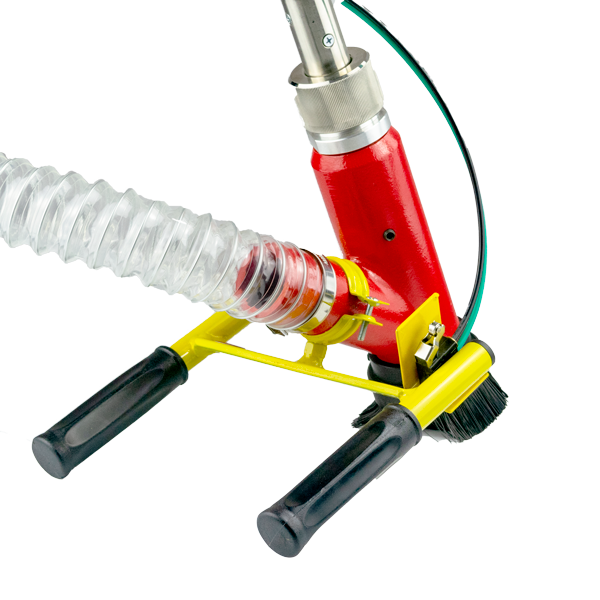

The Pressure BAG recovery sandblaster is supported by the innovative 221 PULSE industrial vacuum cleaner equipped with a continuous bag collection system.

Thanks to this practical recovery system, the operator never comes into contact with dust or processing waste, both during the sandblasting phase and in the disposal phase.

The special cyclone placed on the upper part of the sandblaster allows the separation from the dust and the recycling of the abrasive used.The self-cleaning of the filter cartridges, which takes place in a few seconds, involves an effective counter-blowing action of the cartridges.The action of the 221 PULSE single-phase industrial vacuum cleaner ensures the conduction of waste material inside the continuous Longopac collection bag.

Advantages of Continuous Bag Recovery Sandblaster

Continuous Bag Dust Recovery

The continuous bag recovery system allows for efficient management of the dust generated during sandblasting. This system not only improves the cleanliness of the work site but also reduces operational costs through the reuse of the abrasive.

Recycling Sandblasting

The ability to recycle the abrasive makes sandblasting more sustainable. By reducing the amount of new abrasive needed, waste production and disposal costs are also decreased.

Dust-Free Sandblasting

The continuous bag recovery sandblaster is designed to minimize dust dispersion, creating a cleaner and safer work environment. This is particularly important in industries where air quality is a primary concern, such as the food and pharmaceutical industries.

Operator Safety

Operator safety is a fundamental aspect in any industrial environment. Continuous bag recovery sandblasters significantly reduce exposure to hazardous dust, improving working conditions and reducing the risk of occupational diseases.

Vacuum Sandblaster

Vacuum sandblasters use powerful suction systems to immediately remove dust and residues from the work area. This not only improves visibility during the sandblasting process but also reduces the time needed for post-sandblasting cleaning.

Applications

Industrial Sector

Continuous bag recovery sandblasters are widely used in the industrial sector for cleaning and preparing metal surfaces. They are particularly useful in infrastructure maintenance, paint and rust removal from large steel structures, and surface preparation for painting.

Construction Sector

In the construction sector, these machines are used for cleaning concrete, stone, and brick surfaces. They are ideal for historical restorations, where old paint and contaminants need to be removed without damaging the underlying material.

Other Sectors

Besides the industrial and construction sectors, continuous bag recovery sandblasters are used in numerous other sectors, such as the naval, automotive, and aerospace industries. They are utilized for cleaning and preparing surfaces of ships, vehicles, and aerospace components, ensuring a high-quality finish and extending the lifespan of the structures.

The operator never comes into contact with dust or processing waste, both during the sandblasting phase and in the disposal phase

Want to know more about the Pressure BAG sandblaster? Fill out the form below and we will get back to you as soon as possible.