The Micro Blaster is indispensable for cleaning artifacts of any kind, including wood, stone, mosaics, frescoes, and archaeological finds. Its compact size allows it to be used both on-site and in the laboratory. It features a patented microsandblasting microprojector with remote control, ensuring extremely simple and highly precise use.

The Micro Blaster is a fundamental tool for tasks requiring precision, such as restoration, dentistry, and industry. Used for precision sandblasting, it can remove surface layers without damaging the underlying material. This article explores the features, applications, and benefits of microsandblasting machines

What is a Microblaster?

Subgroup

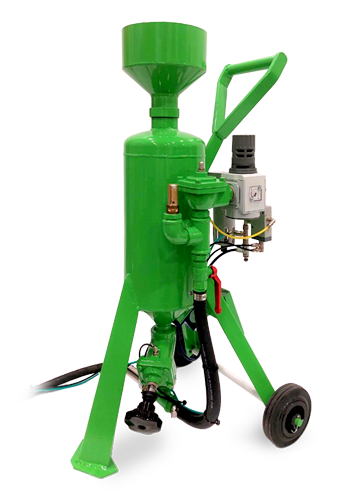

Micro blasters without cabinet

Outstanding Characteristics

Minimal dimensions

1 abrasive

Pedal control

Filter group, pressure reducer, pressure gage

Maximum working protection

Sizable power

The main components of a micro-sandblaster include:

- Abrasive tank: Contains the abrasive material used for sandblasting.

- Sandblasting gun / Microprojector: Directs the abrasive flow.

- Air compression system: Provides the necessary power to project the abrasive.

- Pressure regulator: Controls the intensity of the sandblasting flow.

Number of blasting functions

1 micro jet

- Micro sandblasting system under pressure

- Great punctiformity and precision of the jet

- Low consumption thanks to the dispensing system

- Equipped with pressure reducer, pressure gauge, air filter, pedal control

- Equipped with a 0.8 mm tungsten carbide nozzle

- Abrasive powders to be used: aluminum oxide and glass microspheres

The microblaster uses a compressed air flow to project micro-granule abrasive materials onto the surface to be treated. This allows for precision sandblasting, removing impurities and contaminants without affecting the underlying material. Commonly used abrasives include aluminum oxide, sodium bicarbonate, and glass microspheres.

surface wrinkling is obtained with aluminium oxide;

- with glass microspheres a polishing satin finish with an excellent aesthetic effect (of difficult manual execution) is obtained;

- with abrasives it is possible to carry out removals of varying depths on any surface, depending on the pressure used.

Single use abrasives safe use for inside containers

AL2O3150 (95µ) - AL2O3180 (85µ) - MICROBLAST 90µ

Upon request, the following are available in place of the nozzle and abrasive measuring tool: AL2O360 (250µ) - AL2O3120 (105µ) - AL2O3270 (50µ) SUPERFINE 55µ

Abrasives that are NOT safe for use inside containers

Quantity keeps abrasive in single use containers

500 g ALUMINUM OXIDE or MICROSPHERES

By carrying out the treatment inside a box / cabin, you can take advantage of the protection against the rebound of abrasive grains.

The metal body contains the filter - pressure reducer, the pressure gauge and the connections for the pedal control.

The micro projector is made in a very ergonomic way, similar to a pen, to be handled with maximum comfort and the dispensing nozzle is extremely small so as not to cover the part to be worked.

Nozzles with holes of different sections are available, easily interchangeable, to allow the dispensing of differentiated particle sizes of powders.

Nozzles

1 ø .8 mm (ø .5 / 1.2 /1.5 /2.0 available upon request)

Applications of the Microblaster

Restoration In restoration, the restoration microsabbiatrice is used to remove unwanted layers such as paint or oxides from artworks and cultural heritage items without damaging the original surface. This microsandblasting process is essential for restoring sculptures, paintings, and historical objects.

Dentistry In dentistry, microsabbiatrici are used to prepare dental surfaces before fillings and restorations. Micro abrasion allows the removal of decayed material without compromising the tooth structure, ensuring more effective and less invasive treatments.

Industry In industry, microsabbiatrici are used for cleaning mechanical components, preparing surfaces for painting, and removing surface coatings. The versatility of the aeroabrasion tool allows it to adapt to various operational needs.

Advantages of the Microblaster Precision The ability to control the pressure and amount of abrasive allows for great precision, making the MICROBLASTER precision sandblaster ideal for delicate and detailed work.

Versatility MICROBLASTER FEVI can be used with various abrasive materials, making them versatile tools for different applications. This makes them suitable for both restoration work and industrial interventions.

Portability Many microblaster are designed to be portable, allowing use in different situations and work locations. Portable precision sandblasters offer the same effectiveness as stationary versions, but with the advantage of mobility.

Microblaster represent a valuable investment for anyone needing precision tools for cleaning and surface preparation. In addition to the mentioned applications, regular maintenance and nozzle replacement are important to maintain equipment efficiency. For those working in restoration, adopting FEVI microsabbiatrici with various abrasive granulometries can offer greater control over final results. Finally, continuous training on the use of these tools can significantly improve the quality of the work performed.

Pressure system ideal for carrying out small finishing operations

Would you like to know more about the MICRO BLASTER ? Fill out the form below, and we will get back to you as soon as possible.