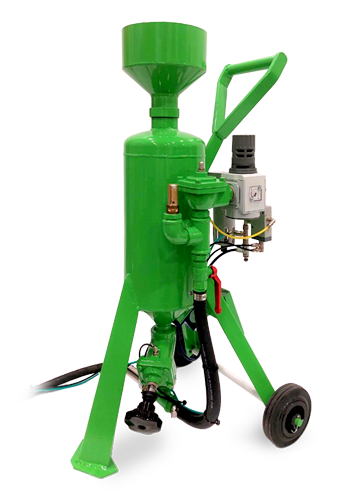

They are systems normally composed of the following parts:

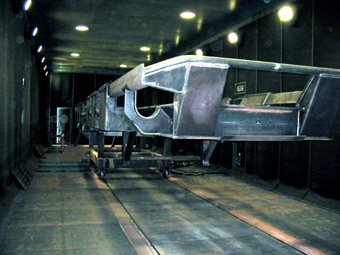

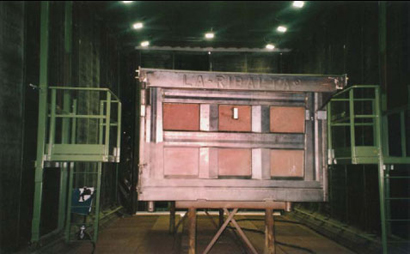

The sandblasting chambers are preferably made with modular press-folded panels with reinforcement ribs that can be assembled by means of bolts.

This solution, more expensive than the welded type, offers the following advantages:

- ease of movement from one place to another

- simplicity in adding a second door

- quick assembly.

To complete the sandblasting chamber there are a series of lamps of adequate power for internal lighting and the internal coating in anti-abrasive black rubber to protect the walls and to contain noise.

The total recovery system of the scraping type abrasive allows to work non-stop without worrying about the abrasive scattered during the processing of the pieces. The aforementioned system provides for the recovery of the abrasive used, for its cleaning and recycle.

The advantages offered by this type of system are the following:

- long service life of the scraping strips

- perfect cleaning of the tanks

- noiselessness

- extremely low foundation costs (H = 200mm.)

- possibility of placing the recovery system directly on the floor (costs for non-existent foundations)

For the dedusting of the sandblasting chambers, our company installs dry dust collectors with self-cleaning cartridges by means of compressed air jets.

During normal maintenance operations the top-loading filter cartridges prevent the operator from accessing the inside of the filter (as per American regulations). This type of filter allows us to ensure excellent visibility inside the sandblasting chambers and also to contain emissions to the exhaust stack within 2/3 mmgr / Nmc max.

The system is completed by a standardised electrical panel designed to avoid abrasive clogging and to ensure control of all electrical equipment