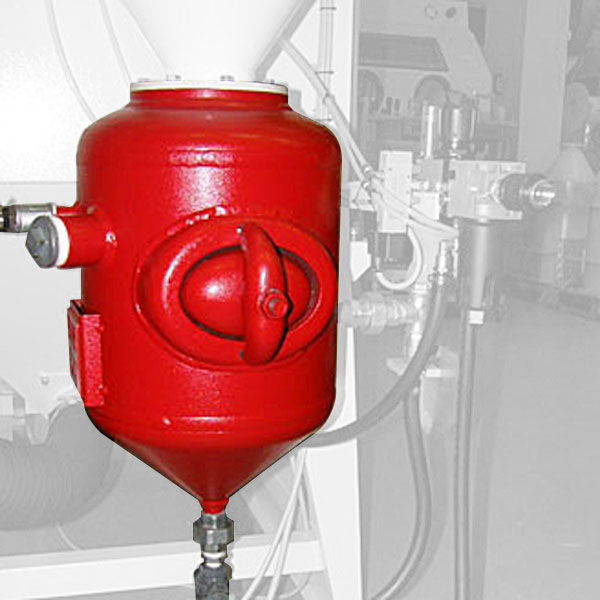

In the rear Italjet Plus sand blaster is provided with a system called cyclone constantly recovering and removing the abrasive used. It is a two-way suction cyclone allowing to work with a wide range of abrasives.

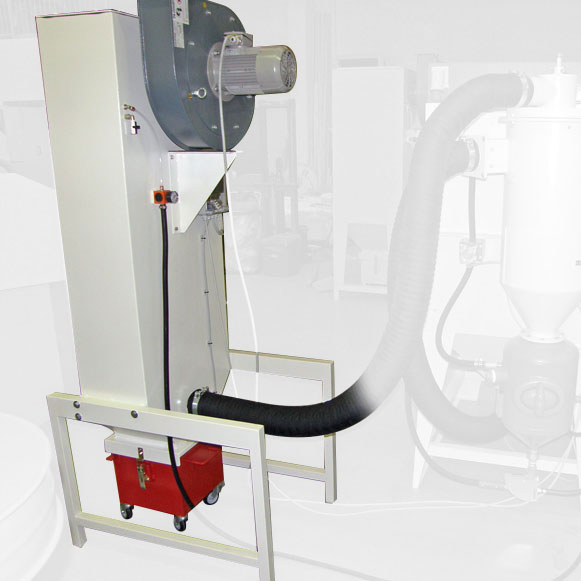

Italjet Plus pressure sand blaster is provided with a filtration system with self-cleaning cartridges. Filtering devices are made of polyester, instead of paper, hence extremely solid. Timed cleaning occurs by a system of automatic blow moulding.

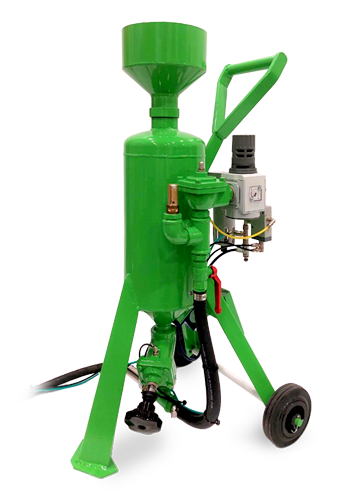

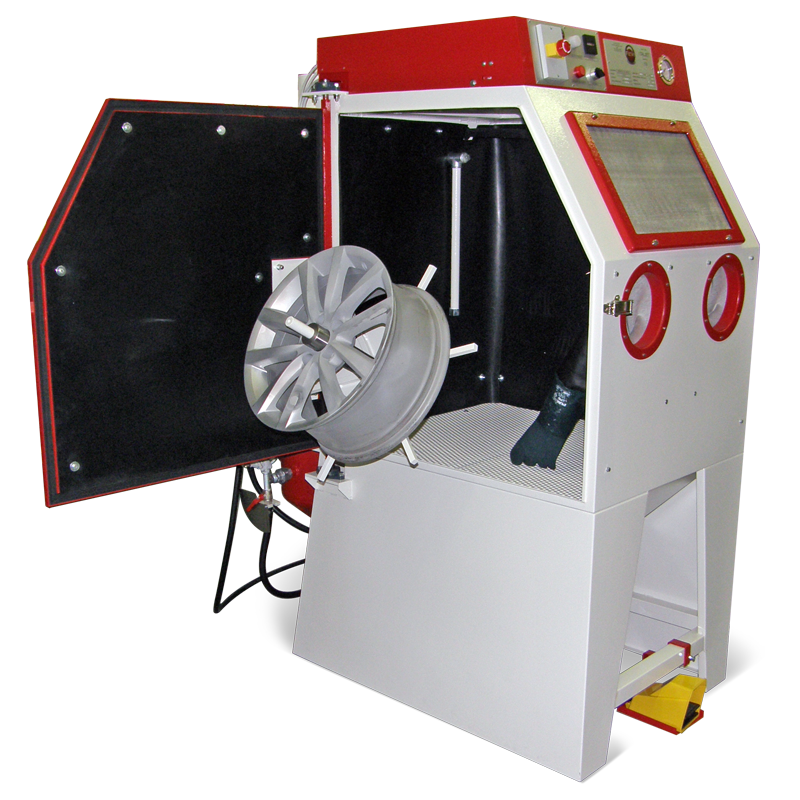

Each detail of Italjet Plus sand blaster is treated with the utmost care: a search for the best components ensures the best working conditions and safety for the operator, both in terms of structure and reliability.

Although concerning an industrial system, Italjet Plus sand blaster dimensions take up the minimum space required.

Thanks to the maximum compactness of the two units, it is always easy to find it a dedicated area in the work environment.

COMPRESSED AIR CONSUMPTION

At 6 bars with a 4mm nozzle, consumption is about 1100 litres/1'. At a lower pressure, consumption proportionately decreases.

POWER SUPPLY

three-phase 400 Volts, 50 HZ, with approximately 24 Volt auxiliary circuits. The system is worked out according to the best technique and with components of ensured quality. All cables are identifiable according to instructions provided in wiring diagram. About 1,5 kW total power draw.

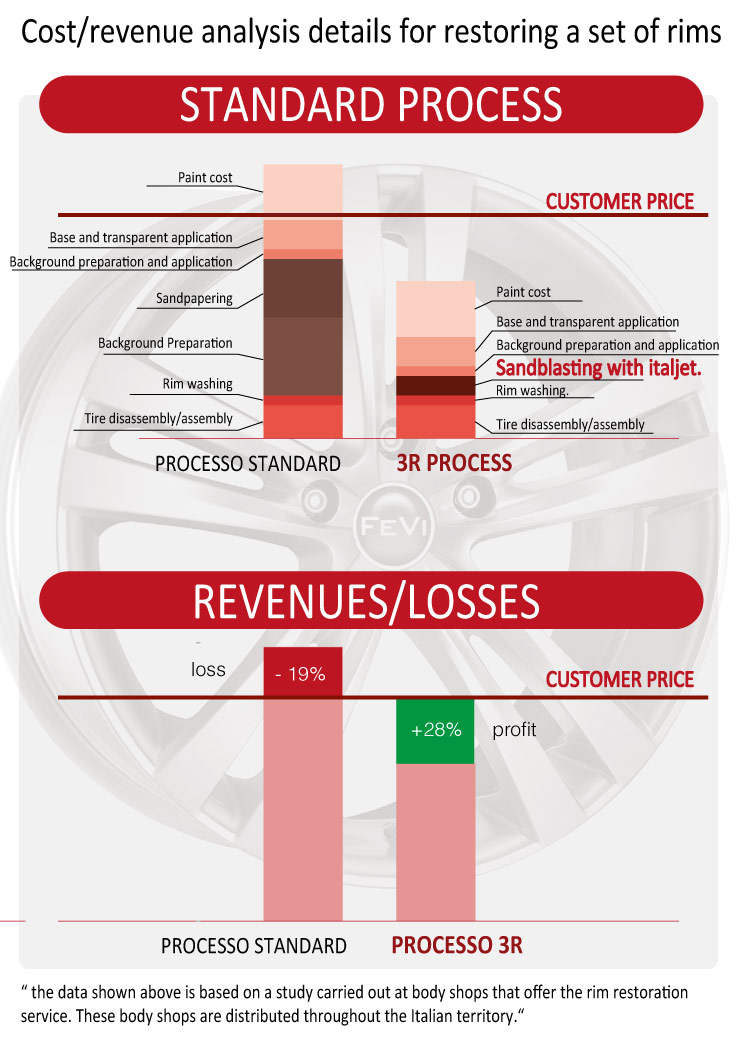

I would like to restore and renew alloy wheels..."

From a difficult request to a business opportunity

The 3R process arose from the experience gained by our company in the smart repair and car refinish sectors, and from our close collaboration with the largest manufacturers of paints and equipment for car bodies and repair shops.

The process of sandblasting and regeneration of alloy wheels with Italjet is part of a new type of offer addressed to the customer, aimed at enhancing the services offered and the consequent customer loyalty.

This path is based on the synergy between all the main workshop activities: from mechanics to electronics, from bodywork to tire service, all the way to the inexorable changes taking place in the world of car repairs.

A significant conclusion emerges from the most recent market analyses: namely, the growth of multi-service body shops and car repair shops organized to offer the customer full service, with the aim of achieving the following objectives:

- Diversifying the business by serving more vehicles in the repair shop

- Creating new opportunities for further checks and repairs

- Improving flows by reducing operating costs and processing times

- Increasing product quality and customer service

- Reducing costs and waste in the production processes

- Optimizing the management of spaces and work areas

- Motivating staff by improving working conditions and worker satisfaction

In the market, the demand for Smart Repairs (fast repair techniques) highlights the need to operate with maximum speed and efficiency with regard to different kinds of activities, such as the repair of scratches, the removal of dents without painting, the repair of glass and windshields and the restoration of alloy wheels by sandblasting.

WHY ABANDON THE CLASSICAL MANUAL AND ORBITAL SANDING?

“Our analyses and our experience confirm with certainty that the blasting process using Italjet improves treatment quality, allowing a 50% reduction in the time required for the preparation of the rim for new painting; it reduces the costs of labour and related consumables, and, consequently, reduces the time needed to deliver the car to the customer”

F. Viglioli

The Italjet Plus Cabin is composed of:

La mandata in pressione del serbatoio genera la spinta dell’abrasivo che fuoriesce sviluppando un getto continuo , di grande potenza e portata