Abrasive Blasting Fittings: Essential for Efficiency and Safety

Abrasive blasting fittings are crucial components for ensuring the optimal operation of blasting systems, providing secure and leak-free connections between the various elements of the setup. Our company, FEVI, specializes in solutions for abrasive blasting and surface treatment, offering a wide range of fittings designed to meet the specific needs of various industrial applications.

The Importance of High-Quality Fittings

Using high-quality fittings is essential to avoid common issues such as air or abrasive leaks, which can compromise the effectiveness of the blasting process and increase the safety risks for operators. Blasting fittings must be corrosion-resistant, durable, and capable of withstanding the typical operating pressures of blasting systems.

Types of Abrasive Blasting Fittings

- Quick Connect Fittings: These allow for easy and fast connection and disconnection, ideal for operations that require frequent changes in configuration.

- Brass Fittings: Known for their corrosion resistance, they are suitable for harsh environments and industrial applications.

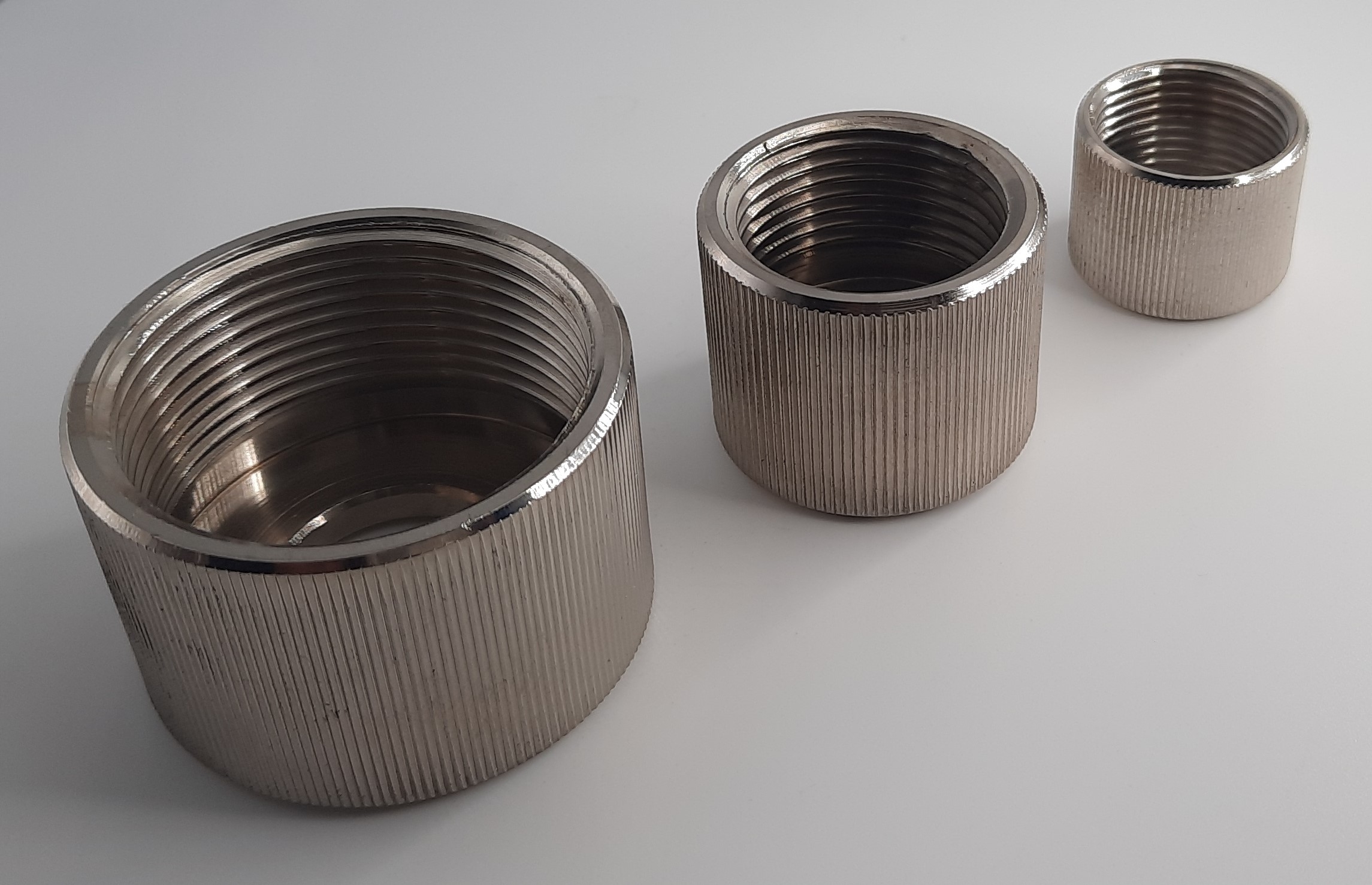

- Stainless Steel Fittings: Offering maximum corrosion resistance, these fittings are perfect for high-pressure applications where greater durability is required.

Maintenance and Replacement of Fittings

Regular maintenance of fittings is essential to ensure their longevity and efficient operation. Periodic checks to identify signs of wear or damage can prevent leaks and inefficiencies. Immediate replacement of damaged fittings is recommended to maintain high safety and performance standards.

Related Products

On our website, you can also find a selection of other essential components for abrasive blasting:

- Blasting Nozzles: Available in various configurations and materials, such as tungsten carbide and boron carbide, to suit different operational needs.

- Blasting Hoses: Designed to withstand abrasion and operational pressures, ensuring a safe flow of abrasive and compressed air.

- Blasting Filters: Essential for keeping compressed air clean and protecting the system from contaminant particles.