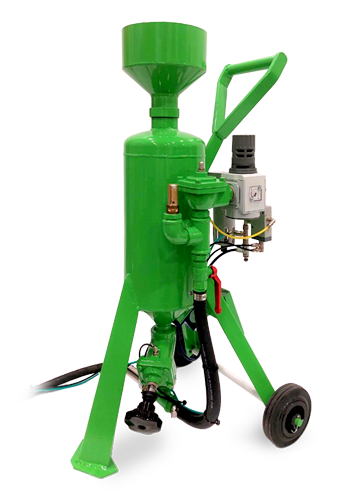

The Pressure MAX sandblasting machine represents a technological evolution compared to previous models thanks to its most powerful suction unit. This increase in performance allows you to tackle different industrial applications more effectively and quickly, further improving safety and operational efficiency.

Thanks to an innovative cyclic cleaning system located inside the extractor, filter cartridge counter-blowing is performed and they are thus thoroughly cleaned.

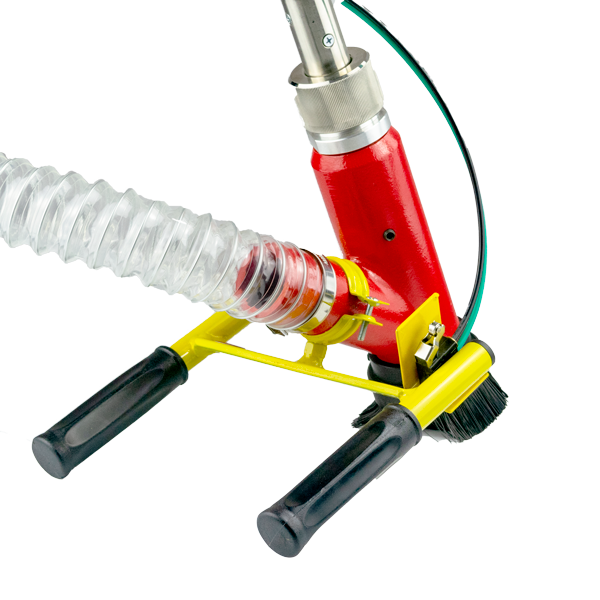

The sandblasting system uses a handle with a front brush that enables to recover and recycle the abrasive used and to consequently separate from the dust generated by surface removal.

The presence of a specific cyclone on the upper part of the sandblasting unit allows the recycling of the abrasive used and to collect the waste material inside the collector drum.

Applications of the PRESSURE MAX recovery sandblaster

- Cleaning and Polishing of Welds on Stainless Steel Products

Thanks to the power of the suction unit, this sandblasting machine offers even faster and more effective cleaning and "polishing" of stainless steel welds, reducing the need for chemicals and improving surface quality. - Creation of Writings and Decorations

Perfect for work on marble, glass, crystal, wood, steel, and ABS. The Pressure MAX recovery sandblaster guarantees precise and detailed results while minimizing the risk of damaging surrounding areas. - Sandblasting of post-machining cylinders Mechanical

With its higher suction capacity, this sandblasting machine is ideal for cleaning cylinders after mechanical machining on a lathe, with the possibility of automating the process by locking the brush head with a tool clamp. - Localized Interventions on Metal Products

The Pressure MAX recovery sandblasting machine allows to perform targeted blasting on metal products or welding seams with precision, preserving the adjacent areas and ensuring clean operations without collateral damage. - Cleaning of Architectural Details Ideal for staircases, stone, marble or granite balconies. The high suction power of the Pressure MAX allows thorough cleaning without blocking the passage of people or protecting furniture and machinery, thus simplifying the operation. Ideal for staircases, stone, marble or granite balconies. The high suction power of thePressure MAX allows thorough cleaning without blocking the passage of people or protecting furniture and machinery, thus simplifying the operation.

- Paint Stripping of Metal Surfaces In the industrial, marine and steel industries, this sandblasting machine is perfect for stripping metal surfaces. It is particularly useful in situations where free jet blasting cannot be used or where it is necessary to work indoors, offering an efficient and safe solution for paint removal.

Thanks to these applications, the PRESSURE MAX suction sander stands out for its superior performance and the ability to handle complex operations more effectively.

The innovative cyclic cleaning system inside the vacuum performs a counter-blowing action on the filter cartridges which are subjected to thorough cleaning

Want to know more about Pressure max recovery sanblaster? Fill out the form below and we’ll get back to you soon